Our vision is affordable custom quality furniture for everyone

At Reforest Design, we specialize in crafting made-to-order sustainable bamboo furniture with an unwavering commitment to quality. Our mission is to safeguard forests, eliminate global furniture waste, and provide affordable solutions. Experience furniture with a purpose – beautifully crafted, sustainable, and tailored to your needs.

Read our full Benefit Statement

Our Story

Design

Each design we craft revolves around a meticulous focus on comfort, quality, longevity, ease of repair, creative expression, production ethics, and environmental preservation. These foundational principles guide the creation of our furniture, leading to designs that continuously evolve and improve with each year of acquired wisdom. While drawing inspiration from Japanese and Mid-Century design, our aesthetic serves as a backdrop to the fundamental essence of our work—understanding and addressing the needs of the human body. Acknowledging the physical and utilitarian aspects of our bodies, we embark on a journey that begins with prioritizing well-being. Our distinctive LOW collection is a testament to our commitment, seamlessly blending utility with innovative approaches to low seating positions. This collection encourages the body to stretch, build muscle, and improve posture, unveiling new dimensions of comfort and health.

Production

How Far We've Come!

-

From Humble Beginnings (with a Baby on Board!)

Our journey started in a small, sometimes messy, but always love-filled studio—passion was our driving force. In those early days, Ewelina often had her little one snuggled up in a carrier while she packaged orders and handled the softer tasks. With a baby on board, we went full throttle, turning dreams into reality one step at a time.

Since then, we’ve expanded our space and grown beyond those humble beginnings, but the heart of our work remains the same: creativity, dedication, and a whole lot of love. -

Our Journey Together

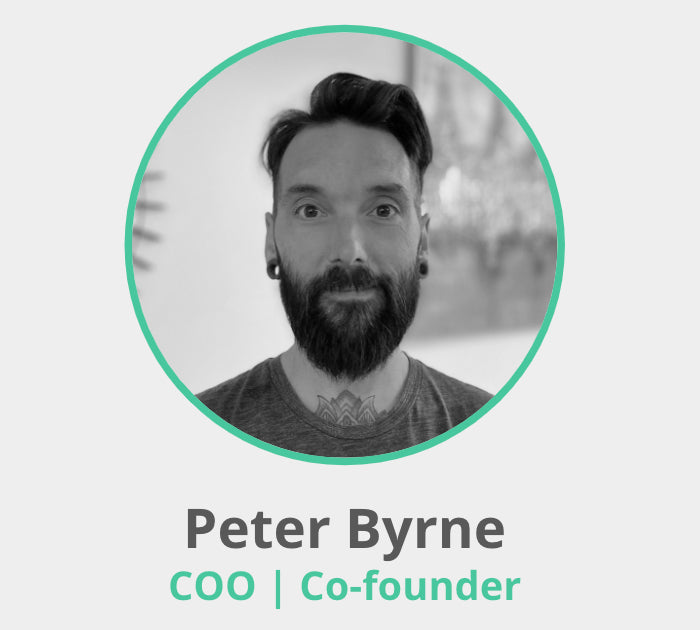

This is us July 2025! We’re lucky to have an incredible team that makes everything we do possible. Gray (far right in photo) is an essential part of our production, keeping things running smoothly as we continue to grow and scale.

We’ve also been supported along the way by wonderful past team members, including David Rankin and Laurence Cruz, whose contributions helped shape the journey. From day one, our work has been fueled by passion, care, and the collective heart of everyone who’s joined us along the way.